PRESSURE REGULATOR SUMMARY

Does your application require the use of a pressure regulator? Before you choose the regulator that best fits your needs there are many design parameters to consider. Does your regulator need to be relieving or non-relieving? Do you need a single, dual or three stage regulator? What range of inlet pressures will the regulator be exposed to? What is your desired outlet pressure? Will you be sending gas or liquid through the regulator? Will you be testing the regulator with or without flow (dead ended)? What temperature will the seals in the regulator be exposed to? Do you have limited space to work with and need something compact? Please read on and learn which regulator will provide the best performance for your demanding application. Once you have narrowed down your requirements you can find our selection of pressure regulators at:

Beswick Engineering Regulators

RELIEVING or NON-RELIEVING:

RELIEVING:

A relieving (also known as self-relieving) regulator allows excess downstream pressure to be vented to atmosphere. For example if you set a relieving regulator to an outlet pressure of 30 psi and then decide to reduce the outlet pressure setting to 10 psi the relieving regulator will vent the excess downstream pressure (20 psi). This will allow the outlet pressure to immediately decrease to the desired 10 psi set point even if there is no flow (dead ended). A relieving regulator is usually more convenient to use in pneumatic systems because you can easily decrease the downstream pressure even if there is no flow.

NON-RELIEVING:

A NON-relieving regulator will NOT vent excess downstream pressure to the atmosphere. For example, if you set a NON-relieving regulator to 30 psi output and then decide to reduce the outlet pressure to 10 psi the NON-relieving regulator will NOT immediately decrease to the desired 10 psi if there is no flow (dead ended). If there is flow, the output pressure will decrease to the desired set point as the excess downstream pressure is consumed. A NON-relieving regulator is preferred for use with liquids and hazardous, explosive, or expensive gases because no fluid is allowed to vent to atmosphere.

SINGLE, DUAL, OR THREE STAGE REGULATOR:

| SINGLE STAGE: | Inlet Pressure Range: | Up to 500 psig |

| Outlet Pressure Range: | 0 to 400 psig (PR piston regulator) | |

| 5 to 45 psig (PR-MLS piston regultor) | ||

| 0 to 30 psig (most diaphragm regulators) |

A single stage regulator is recommended for applications where the inlet pressures will remain relatively constant over time.

Single Stage Piston Regulators: PR-MLS | PR

Single Stage Diaphragm Regulators: PRD | PRDB |PRDB-18MM | PRDB8 | PRDHF | PRDHF8

| DUAL STAGE: | Inlet Pressure Range: | Up to 500 psig |

| Outlet Pressure Range: | 0 to 30 psig (most diaphragm regulators) |

A dual stage regulator is well suited for applications involving fluctuating inlet pressures over time, for example with compressed gas cylinders or tanks. As the gas is depleted from the tank the second stage in the regulator will compensate for the decreased inlet pressure, resulting in stable outlet pressures. When stable delivery pressures are critical a dual stage regulator is ideal.

Dual Stage Regulators: PRD28 | PRD3

| THREE STAGE: | Inlet Pressure Range: | Up to 3000 psig |

| Outlet Pressure Range: | 0 to 40 psig |

A three-stage pressure regulator accurately reduces high pressures up to 3,000 psig. The three stage regulator minimizes droop or rise, even with wide swings in inlet pressure. It is an excellent choice for applications with decaying inlet pressures and is especially suited for use with high pressure disposable cylinders.

Three Stage Regulators: PRD3HP | PRD4HP

OUTLET PRESSURE RANGES:

If you are using a higher outlet pressure range (30-400 psig) or a very low outlet pressure range (0-30 psig) Beswick has the right regulator for the job. We manufacture both diaphragm and piston style regulators to satisfy your design requirements.

Applications specifying higher outlet pressure ranges (30- 400 psig) are best suited for Beswick’s piston design. Applications requiring a low outlet pressure range (0-30 psig) are ideal for Beswick’s diaphragm design.

Using a low outlet pressure range (0-30 psig)?

| Beswick’s Diaphragm Regulators are manufactured with a sensing area that is much larger than a piston style regulator. This larger sensing area allows the regulator to be more responsive to smaller changes in outlet pressure. This makes diaphragm pressure regulators well suited for applications involving low set points and/or requiring a higher degree of accuracy. |

Using a high outlet pressure range (30-400 psig.)?

| Beswick’s piston regulators are best suited for applications with higher outlet pressure ranges, up to 400 psig. These regulators work well with higher outlet pressure settings, but result in more noticeable hysteresis at very low outlet pressures and flows. |

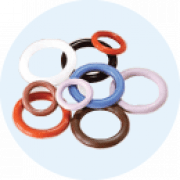

SEAL MATERIALS:

| Beswick’s regulators are assembled with Buna-N O-rings and diaphragms unless otherwise noted. Buna-N satisfies a wide range of applications, but if your application involves extreme temperatures or corrosive fluids, Beswick offers several other seal materials including EPDM and Viton. Please speak with one of our Applications Engineers for assistance in selecting the best material for your application. We also offer a general guide to the benefits of each seal material here. |